Generally speaking, CNC machine tools need to be Geared up with sufficient tools to fully benefit from their functions, enabling the machine to process various products and solutions and stay away from idle time and squander.

Make the most of many trade exhibits to decide on equipment that is certainly of high top quality, cheap, and responsible overall performance and Evaluate choices.

The relative movement in three-dimensional Area has six levels of independence, such as three translational degrees of liberty and 3 rotational levels of flexibility. By introducing two rotational levels of flexibility In combination with the translational levels of liberty inside the X, Y, and Z Instructions, as well as rotational diploma of independence for cutting the Device itself, the five-coordinate linkage delivers all six levels of flexibility with the relative movement among the tool as well as the workpiece, allowing for the Device and workpiece to be in any relative situation and orientation.

Inside the dynamic entire world of manufacturing, CNC machines have remodeled how we generate intricate patterns from raw supplies. This weblog delves into the interesting realm of CNC machining, highlighting their pivotal job in contemporary field. Understand the precision, automation, and flexibility that make CNC machines essential for high-excellent production.

Alternatively, vertical machining is a lot more precise and perfect for smaller workpieces. Having said that, this has its down sides. It doesn't enable the machining of deeper cuts due to vibration, resulting in deviations from models.

Several suppliers will counsel they may have an excellent guarantee but will never exchange wearable areas like a spindle. Get your time and effort and ensure everything is evident and upfront on their own finish.

To quickly establish and solve system faults, it is vital to maintain the fault analysis course of action as very simple and efficient as you can, reducing time required for prognosis. To obtain this, the subsequent diagnostic procedures could be employed:

The Software changer enhances the here productivity of the vertical machine center by permitting the automatic choice of tools for various jobs ranging from rough cutting to fantastic-hole unexciting.

Intricate CNC machining components have to have advanced CNC equipment or the usage of many machines. As a result, the familiarity with machine abilities and operations is also essential for correct success.

Regulating the system is The best solution for correcting faults. This can be performed by altering the potentiometer. For instance, inside of a manufacturing unit servicing scenario, In the event the system computer screen is exhibiting chaos, it may be fixed by earning an adjustment.

RapidDirect is a leading manufacturing enterprise located in China having an advanced manufacturing manufacturing facility with two hundred+ CNC machines in twenty+ classes. We have been working with automotive, aerospace, professional medical, hardware, electronics, together with other a number of industries around the world to produce CNC machine components.

When beginning, run the tool magazine and manipulator empty to start with to check that each one sections are performing normally, notably paying attention to the operation of all vacation switches and solenoid valves.

Parameter Verify the machine details on the NC machine Software is an important parameter attained via a series of exams and changes, and that is the promise of the normal Procedure of your machine Resource.

Machine tools check with a set of mechanical components immediately linked to the machining approach, such as spindles, drives & motors, and desk slides.

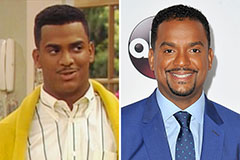

Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Keshia Knight Pulliam Then & Now!

Keshia Knight Pulliam Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Lisa Whelchel Then & Now!

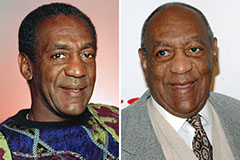

Lisa Whelchel Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now!